New testing and other standards for producing sprouts – which have been associated with various foodborne illness outbreaks – is one of the key elements of the now final FDA Food Safety Modernization Act (FSMA) Produce Safety rule in the United States.

According to the FDA (US Food and Drug Administration), the measures on sprouts aim to prevent contamination with dangerous microbes, such as Listeriamonocytogenes. It said other key elements of the new rule are:

- Requirements for agricultural water quality and testing are designed to detect contamination by feces, which may be accompanied by bacteria that cause disease.

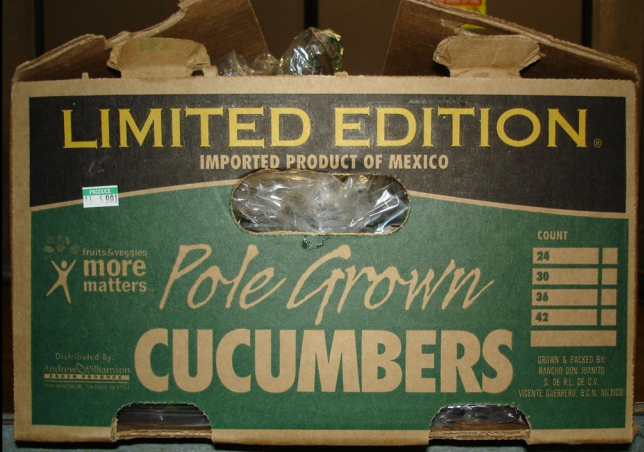

- Requirements affecting use of biological soil amendments of animal origin (including manure and compost), which will help reduce the likelihood of potentially dangerous bacteria entering the food supply.

- A requirement that during harvest, farmers take all reasonably necessary steps to identify potential contamination (including contamination by animals) and not harvest the affected produce. This is in recognition of the fact that there are often animals on farms, such as livestock, and even wild animals, like deer.

- Farm workers handling covered produce and/or food contact surfaces, including their supervisors, must be trained in the importance of health and hygiene and farms must take steps to prevent contamination of produce and food-contact surfaces by people who are sick.

- Standards applying to equipment, tools and buildings (including greenhouses and germination chambers), which aim to prevent problems, such as poor sanitation, causing produce contamination.

The FDA said the new rule is all about “keeping food safe for consumption.” It establishes “mandatory science-based, minimum standards for the safe growing, harvesting, packing, and holding of fruits and vegetables grown for human consumption.”

According to The U.S. Apple Association (USApple), the ‘Standards for the Growing, Harvesting, Packing, and Holding of Produce for Human Consumption’ will be officially published on November 27 and become effective 60 days later.

“Compliance to the rule is staggered over several years depending upon the specific provision and size of the operation,” the association said.

“The rules are the most significant changes to produce safety regulation in 70 years, and have the potential to significantly affect tree fruit production practices,” it said. USApple has been actively advocating on behalf of the apple industry during development of the FSMA rule. “In particular, we focused on the Agricultural Water provisions in the second round of comments to the FDA. As a result, the agency added additional flexibility to the Agricultural Water provision in the final rule,” it said.

Read more about the FSMA Final Rule on Produce Safety here: http://www.fda.gov/Food/GuidanceRegulation/FSMA/ucm334114.htm